Brushless motor vs brushed in today’s fast-paced world, electric motors play a pivotal role in various industries, from automotive to robotics and beyond. Among the numerous motor types available, two major contenders have been locked in a constant duel: the brushless motor and the brushed motor. These electric powerhouses are appropriate for various applications due to their unique characteristics. In this comprehensive guide, we’ll delve into the world of electric motors, comparing the brushless motor vs brushed motor in terms of design, performance, efficiency, and applications. You’ll know for sure by the end which motor best meets your individual requirements.

The Fundamentals: Brushless vs. Brushed Motors

Before we dive into the comparison, let’s get a brief overview of what brushless and brushed motors are.

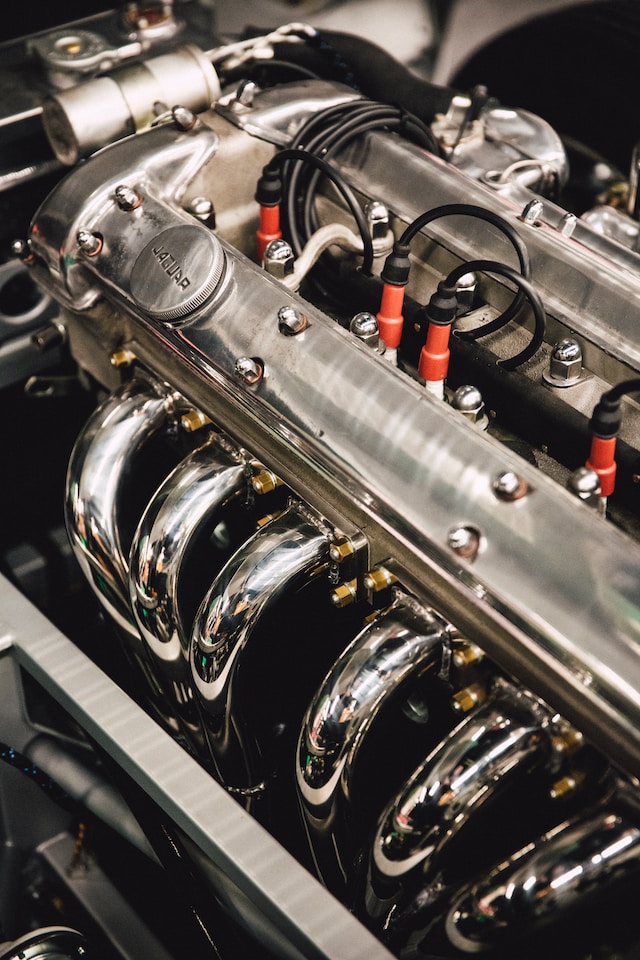

Brushed Motors

Brushed motors, also known as DC brushed motors, have been around for over a century. They function according to electromagnetic principles. In a brushed motor, a rotor (armature) spins between two magnets. Brushes, usually made of graphite or carbon, make contact with a commutator, transferring electrical current to the armature. This interaction creates a rotating magnetic field, which generates mechanical motion in the motor.

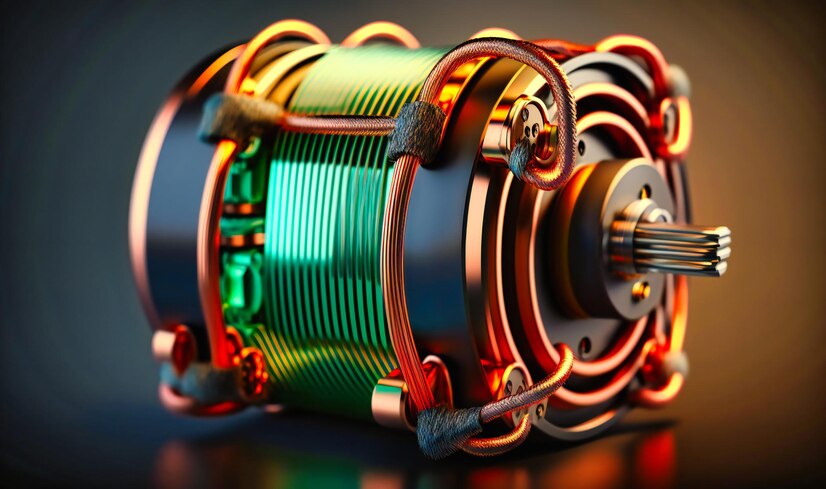

Brushless Motors

Brushless motors, on the other hand, are a more recent innovation. They are often referred to as BLDC (Brushless Direct Current) or simply BL motors. In contrast to brushed motors, they eliminate the need for brushes and commutators. Rather, they create a rotating magnetic field that drives the rotor by using electronic controllers to reverse the direction of current flow in the motor’s coils.

Now that we have a basic understanding of both types, let’s compare them across various dimensions.

Design and Structure

The design and structure of brushless and brushed motors are fundamentally different, which leads to significant variations in their performance.

Brushed Motor Design

- Simplicity: Brushed motors have a relatively simple design, consisting of fewer components. This simplicity can make them cost-effective and easier to manufacture.

- Brushes and Commutators: As mentioned earlier, brushed motors rely on brushes and commutators, which wear out over time. As a result, lifespan and maintenance needs are reduced.

- Low Efficiency: Brushed motors tend to be less efficient compared to brushless motors because of energy losses due to brush friction and the fixed magnetic field.

Brushless Motor Design

- Complexity: Brushless motors are more complex in design due to the electronic controllers needed for operation. Nonetheless, more control and efficiency are made possible by this intricacy.

- Durability: Since brushless motors lack brushes and commutators, they have a longer lifespan and require minimal maintenance. They are therefore appropriate for uses where dependability is essential.

- High Efficiency: Brushless motors are renowned for their high efficiency, thanks to reduced energy losses and precise control of current flow. This efficiency results in less heat generation and longer operating times.

Performance and Efficiency

When it comes to performance and efficiency, the brushless motor has a clear advantage over its brushed counterpart.

Brushed Motor Performance

- Limited Speed Control: Brushed motors have limited speed control options. Adjusting the speed often involves changing the voltage, which can lead to inefficiencies.

- Lower Torque: Brushed motors generally provide lower torque at higher speeds, making them less suitable for applications that require high torque and precision.

- Brush Wear: The brushes in brushed motors wear down over time, affecting performance and potentially causing electrical arcing, which can damage the commutator.

Brushless Motor Performance

- Precise Speed Control: Brushless motors offer precise speed control and can maintain a consistent speed regardless of load conditions. This makes them ideal for applications requiring stable and accurate performance.

- Higher Torque: Brushless motors provide higher torque at lower speeds, making them suitable for applications that demand both power and precision, such as robotics and electric vehicles.

- No Brush Wear: Since brushless motors don’t rely on brushes and commutators, they are virtually maintenance-free and can operate reliably for longer periods.

Efficiency and Energy Savings

Efficiency is a critical factor when comparing brushless and brushed motors, especially in applications where energy consumption is a concern.

Brushed Motor Efficiency

- Lower Efficiency: Brushed motors tend to be less efficient due to the friction between brushes and commutators, which generates heat and results in energy losses.

- Heat Generation: The inefficiency of brushed motors leads to more heat generation, which can be problematic in applications where overheating is a concern.

Brushless Motor Efficiency

- High Efficiency: The high efficiency of brushless motors is well-known. The electronic control of current flow minimizes energy losses, resulting in less heat generation and improved overall efficiency.

- Energy Savings: In applications where energy efficiency is paramount, such as electric vehicles, brushless motors are the preferred choice due to their ability to conserve energy and extend battery life.

Applications

The choice between a brushless and a brushed motor largely depends on the specific application’s requirements. It’s common knowledge that brushless motors have high efficiency.

Brushed Motor Applications

- Household Appliances: Brushed motors are commonly found in appliances like vacuum cleaners, blenders, and power tools due to their simplicity and cost-effectiveness.

- Low-Cost Toys: Simple toys that require basic motor functions often use brushed motors because of their affordability.

- Automotive Accessories: Some automotive accessories, such as windshield wiper motors, still utilize brushed motors.

Brushless Motor Applications

- Electric Vehicles (EVs): Brushless motors are the heart of electric vehicles, providing efficient and precise propulsion.

- Drones and Quadcopters: The high efficiency and precise control of brushless motors make them ideal for drone propulsion.

- Industrial Robotics: Brushless motors are extensively used in robotic arms and automation systems due to their reliability and accuracy.

- Computer Hard Drives: Brushless motors are employed in computer hard drives to ensure stable and reliable disk rotation.

Conclusion

In the battle of brushless motor vs. brushed motor, both have their strengths and weaknesses. Brushed motors offer simplicity and cost-effectiveness, making them suitable for certain applications. However, when it comes to efficiency, durability, and precise control, brushless motors take the lead.